Introduction to Turning

This article is intended for those who are new to machining and seeking to gain some insight.

Machining is a manufacturing process where metal is removed, as opposed to an additive process such as 3D printing. There are several types of machining:

turning

milling

drilling

grinding

electric discharge machining (EDM)

hobbing

water jet cutting

laser cutting

shaping

skiving

honing

Turning and milling are the most common processes and this article focuses on the former.

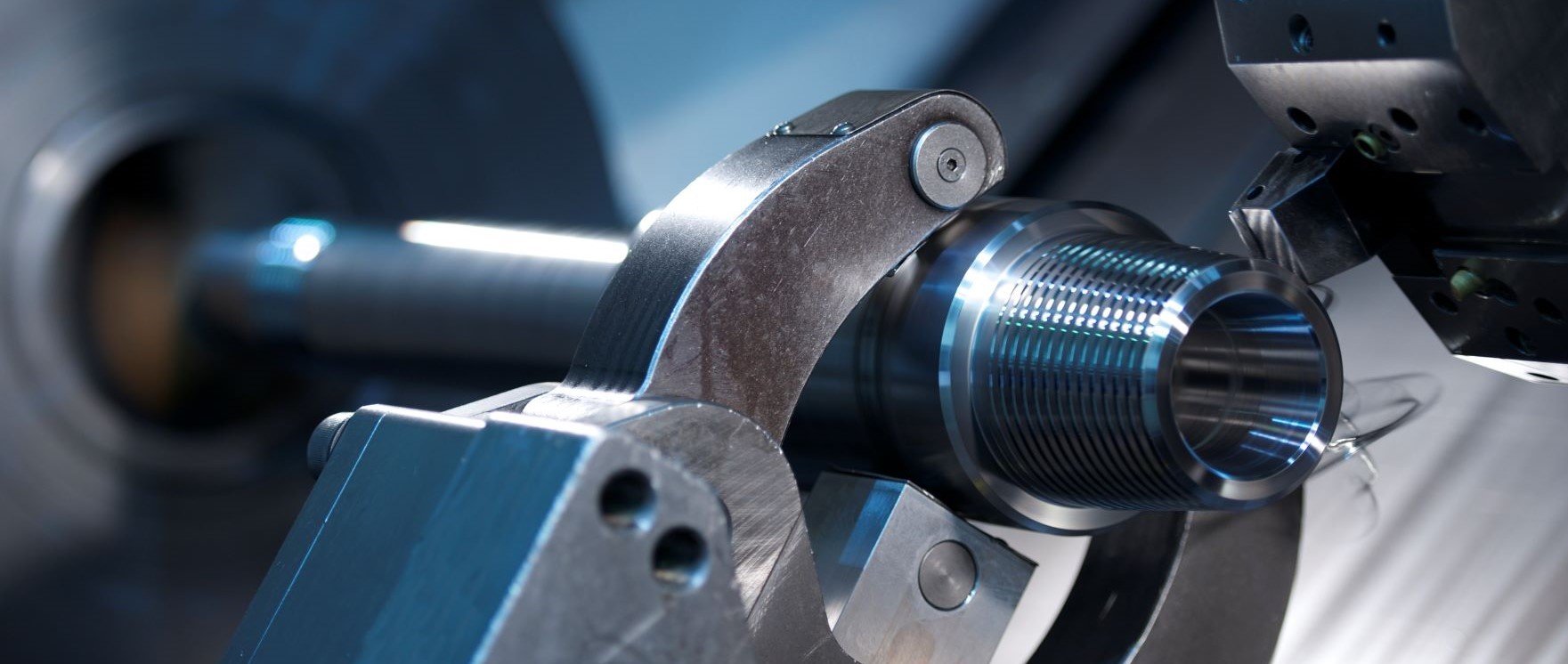

Turning is a process where the part being machined spins and the cutting tool moves along the spinning part to create its net shape. The machine used for this process is called a lathe. This contrasts with a process called milling where the tool spins instead of the part, which remains stationary. There are several different types of lathes, but a spinning workpiece is common between them. A common type of lathe called a horizontal, slant bed CNC lathe is pictured in Figure 1 below. Some examples of turned parts are include shafts, flanges, pins and housings. A before and after CAD drawing of raw material turned into a shaft is depicted in Figure 3.

The following references figures 1, 2 and 3 which are different views of a lathe CAD drawing with the sheet metal and control panel removed for clarity:

A lathe’s foundation is called the bed which acts as the base of the machine to which other components are attached.

A spindle motor drives the spindle via belts, which in turn drives a chuck. Although not shown here, a lathe may have a gearbox between the motor and spindle, like a transmission in a car.

The spindle is not typically visible and is located in the headstock, along with the spindle bearings and drawtube (used to move the chuck, if hydraulic).

The chuck holds the part being cut (the workpiece; yellow color in Figure 1).

A cutting tool, in Figure 2, cuts the spinning workpiece and removes material to produce the net shape of the part.

Other motors are located on the X and Z axis as well at the turret. The X and Z motors move each axis via a ballscrew.

The turret can hold multiple tools and rotates each into position via the motor as needed. There is only one tool in the Figure 1.

Figure 1: Several views of a CNC Horizontal Slant Bed lathe. Sheet metal and control panel removed for clarity

Figure 2: An Outside Diameter (OD) cutting tool.

Figure 3: Raw material (top) machined into a finished part (bottom).

Controlling movement

This machine is computer numerically controlled (CNC) and is programmed using code. The code is processed by a computer which tells the electric motors which direction to spin, how long, how fast and how quickly to accelerate and decelerate, thus controlling the motion of the axes and spindle. Most modern CNC lathes are very accurate, with the ability to move and come back to a position within a space of 0.0002”. For comparison, a human hair is about 10x larger at 0.002”. A CNC machine would have a control panel which allows for either manual or automatic operations. Lathe manufacturers either purchase third party controls and motors or manufacture their own proprietary designs.

CNC Code

The code the machine is programmed with is more basic than the common computer programming languages such as C++ or Java. Typical code would turn on the spindle, move the tool into position and move at selected speeds and feed rates. Then the code would direct movement along positional geometry using X and Z positions.

The code used in CNC machines varies between manufacturers, but G code is one of the most popular options. Here we’ll go over programming a simple movement and its associated code. In this example, we’ll select the tool we need, turn on the spindle and coolant, quickly move the tool close to the workpiece, feed the tool at our select parameters and rapid the tool back to its home position. The material being cut is 3.0” in diameter. The origin of X and Z axis on a lathe is at the face of the part and at its axis centerline.

T0101 Tool 1, offset 1 is selected. Offset is the position of the tool in the machine and very often matches the tool selection.

G97 S500 M03 rotate spindle at 500 revolutions per minute in a clockwise rotation

M08 Coolant on

G00 X2.9 Z.1 G00 is a rapid move to a diameter of 2.9” and 0.1” to the right of the part face

G01 Z-5.0 F0.012 feed the tool until it reaches 5” at a feed rate of 0.012”/revolution

G01 X3.1 feed the tool to clear the material

G00 G28U0W0 rapid the tool back to its home position

M05 turn off the spindle

M09 turn off the coolant

M30 end the program and jump back to the beginning of the code

Not all code is entered manually point by point. Shortcuts available as a feature in the control are cutting cycles (canned cycles) where the programmer enters the final geometry and cutting parameters and the control creates all its X and Z positions internally. Further programming options could include macro programming where variables and loops are used to automate programming of similar parts and conversational controls which present the programmer a series of options, then generate code internally by the control.

CAD/CAM programming

A lot of programming of the machine tool is also done offline, or away from machine using a PC and computer aided drafting/computer aided manufacturing (CAD/CAM) software. CAD/CAM software is often more sophisticated with more options, control and automation of programming compared to programming on the machine control panel. The part is typically drawn and then tool and tool paths are applied with the software generating code to be uploaded to the machine. Increased file organization is another benefit of programming and saving files offline at a PC. Figure 4 depicts a screen shot of a CAD/CAM programming package.

Figure 4: CAD/CAM programming screen shot.

Setup

The first process in making parts on a CNC machine tool is setup. In this stage, a machinist attaches tools to the machine and secures the material using work holding, such as the chuck in figure 1 (more about work holding down below). The tools are “touched off” (their cutting position geometry input into the machine) and the machined part’s origin is set. Proving out the CNC program, where a program that hasn’t been run previously, may also be part of the setup process. Here, the machinist ensures that parts of the machine do not crash into each other, the tools respond as expected and the shape and size of the part is correct. The machining operation is completed by running thru the program until the end at which point it is ready to run again for the next component. The part is measured to ensure compliance to the drawing or specification. If issues are detected, such as say a rapid tool movement into the component, the program is corrected until the process is correct.

Run

Once the machine is setup, the responsibilities of the machinist differ during the run phase of production, where the program is run repeatedly on each part. Responsibilities include the monitoring of cutting tools and replacing them when necessary, measuring machined part features, troubleshooting machining problems and ensuring chip evacuation.

Tooling

Tooling knowledge is valuable in machining and turning is no exception. Understanding tool materials, toolpaths, cutting parameters, cutting strategies, work holding and the machine tool to machine a particular component to is important to make the part and make it efficiently. You can only select from the tools you know about, so the larger your library of known tools and how they perform, the better.

Tool Materials

As previously mentioned, when turning, the cutting tool moves along the workpiece, which spins, and the cutter continuously moves along its corresponding toolpath. The cutting tool is harder than the material it’s cutting. There are a few different cutting tool options material options: high speed steel, ceramic and diamond, but the most common is tungsten carbide or WC (elemental symbol). Tungsten carbide cutting tools are formed with equal parts tungsten and carbide and mixed with a binder (often cobalt). The mixture is heated and pressed into shape. Once formed the insert is often coated with a thin film via a physical vapor deposition (PVD) or a chemical vapor deposition (CVD) coating, each with their own advantages. A common design of cutting tool in turning consists of an WC insert which is clamped into a steel cutting tool body as shown in Figure 2. The insert, which is hard but expensive compared to steel, is designed to wear with cutting time and be replaced. The cutting tool body may wear or even break eventually but is designed to last much longer than the insert. This combination is cost effective without sacrificing performance.

Toolpaths

The cutting tool moves along the length of the part (Z axis on the machine) and into and away from the part axis (X axis on the machine) on a 2 axis lathe such as Figure 1. The tool will move in specific patterns called toolpaths, and using multiple cuts or passes to avoid overloading and deflection of the tool. For turning there are several common toolpaths such as follows:

· outside diameter (OD) turning - where the tool moves toward the chuck along the parts Z axis

· facing - where the tool moves towards the part center or radially to remove material from the end of the part

· boring – inside diameter (ID) turning where the cutter is inserted into a hole in the workpiece to remove material from the inside

· grooving – a combination of axial and radial movements with a square shaped tool to create grooves

· part off - similar to grooving, except the groove is continued thru wall of the part to remove cause separation

· threading - where a cutting tool which corresponds to the shape of the thread, moves axially towards the chuck in synchronization with the spindle to cut a thread. The tool moves at a specific feed corresponding to the pitch of the thread

Cutting Parameters

In OD turning, the toolpath, feed of the tool, speed of the spindle and depth of cut are all cutting parameters which are chosen for their efficiency on a particular cutting situation which varies with material, part shape and cutting tool. Some definitions are as follows:

· the feed of the tool is the amount the tool advances for each rotation of the spindle and is called out as feed per revolution

· the speed of the spindle is programmed in revolutions per minute (rpm) or surface feet per minute (sfm)

· the depth of cut is the amount of material being removed radially and is specified as distance measurement

The cutting parameters are all chosen based upon the toolpath, material being cut, cutting tool material used and the machine capacity. For example, cutting parameters for OD roughing in 1018 steel using a carbide insert might be 600sfm (surface feet per minute), 0.014”/revolution and a 0.15” depth of cut.

Increasing any of the cutting parameters will reduce tool life with speed having the greatest affect, followed by feed and then depth of cut. The reduced tool life does come with a decreased cutting time thus saving money. The optimization of cutting parameters should be tested to factor in the economics of machining in any process. For example, if a shop has a high hourly rate, but is running tools slowly, it will be more cost efficient to increase cutting parameters even if that means spending more on cutting tools.

Strategies or planning

Successful machining strategies, in turning operations or otherwise, are used to mitigate the risks and gain efficiencies identified thru the entire machining process from start to finish. Sometimes parts are machined in one operation, where the part is finished with one setup of the machine tool and sometimes there are many different stages of the machining process, it all depends on the part. Although going thru all machining strategies are beyond the scope of this author and this article, two common topics worth discussing are as follows: roughing vs finishing and compensating for material movement. You’ll see they are somewhat intertwined.

Roughing vs Finishing

Very often in the machining process, features are rough machined first and then finished afterwards with a different tool, especially in hard metals, such as steel, titanium and inconel. This two stage process allows for faster cutting and consistent sizes of the finished part. Rough machining uses more productive (faster) cutting parameters to save time compared to finishing and creates the near, but not final, net shape. Some material is purposely left over after roughing to allow for finishing the part. The roughing tool will wear faster and deflect away from the cutting material more because of the higher forces used.

The finishing tool path would typically use a lower depth of cut, higher speed and lower feed than roughing. The finishing tool also deflects less and wears more slowly which allows the machinist to repeatedly hold tight tolerances. Tolerances are the allowable limits the machinist is directed to stay within. For example, if a drawing calls for a 1.000 +0.002/-0.000 diameter, the tolerance is .002”. One could also introduce a semi-finishing pass in between roughing and finishing allow for even more consistent material removal between the two.

Machining Induced Stress

Productivity is one reason to rough first, finish second, but material movement is another. After or even during roughing, many metals will move because of the stress induced into the material during heavy cutting. The more aggressive the cuts, the more movement is expected. If the material moves more than is allowed, the machinist has scrap on his hands. Thus, it’s necessary to rough the material and leave enough for finishing to compensate for material movement. Allowing the material to rest between roughing and finishing or stress relieving the material are effective approaches to reduce machining induced stress.

Work holding

Work holding typically refers to the systems or components holding the part being machined. Some common work holding options are as follows:

· Chuck – uses jaws to apply force to the machine part radially. Cylindrical in shape and attached to the spindle. A power chuck could be hydraulic (oil) or pneumatic (air) and often clamps on the round workpiece with the push of a button or pedal. It could also clamp on the inside of a tube. A manual chuck does the same but uses elbow grease to apply the forces using a key or tool. Chucks come in endless sizes and jaw configurations, but a 3 jaw chuck is the most common. One downside is that the jaws concentrate forces at each jaw position and could deform the part being held.

· Collect chuck – uses a collet (a circular wedge mechanism) to clamp down and apply force to the material. Often used with a bar material that is positioned thru the machine spindle and limited in size to Ø3.0” or less. Uses a very consistent force all around the part with less part deformation, however it has a limited in range of motion compared to chucks

· Tailstock –Typically used to support long parts that would deflect and/or chatter with a just a chuck. Hydraulic, pneumatic or mechanical. With the use of a center (a tapered cone), the tailstock is used to apply force axially to the end of the part inside a drilled hole.

· Steady rest – used to support long parts with 3 points radially applying force to the outside diameter of the part. Hydraulic, pneumatic or mechanical.

The Machine Tool

The largest tool in a machinist’s arsenal, the more a machinist is familiar with their machine tool the better. Understanding the machine’s capacity to support machined components, apply cutting force, maintenance requirements and speed limits are important to use the machine effectively. For example, in turning, being able to predict the depth of cut a machine tool spindle motor and turret are able to handle is a lot more efficient than guessing, which risks breaking tools or slowly ramping up depth of cut from a low point. Further examples would be predicting chatter (vibration) situations, understanding the features of the control, and knowing the axis torque limits and how they relate to tools. Most of the above knowledge is gained by experience via trial and error.

Turning is essential turning process for machining cylindrical parts. Amco Manufacturing specializes in turning of large components for the oil and gas industry. Contact us today for machining your turned components.